- Ginazhao@wanglumaterial.com

- Mon - Sat at 7:00AM to 9:00PM

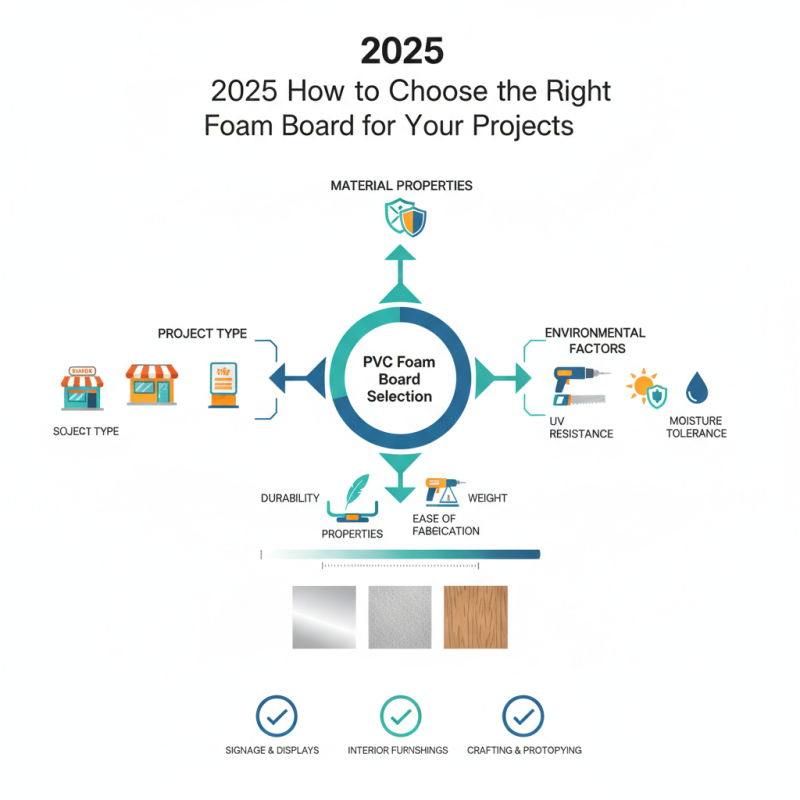

When it comes to selecting materials for a variety of projects, the decision can often feel overwhelming, especially with the multitude of options available in the market. One material that has gained significant popularity is PVC foam board. This versatile product is widely used in applications ranging from signage and displays to interior furnishings and crafting. Understanding how to choose the right PVC foam board for your specific needs is essential for achieving the desired results in any project.

PVC foam boards come in a range of sizes, thicknesses, and finishes, which can influence their suitability for particular applications. By considering factors such as durability, weight, and ease of fabrication, you can make an informed choice that aligns with your project requirements. Additionally, the environment in which the PVC foam board will be used plays a crucial role in the selection process, as certain conditions may necessitate specific features like UV resistance or moisture tolerance. In this guide, we will explore key considerations to help you navigate the world of PVC foam board and select the ideal option for your creative endeavors.

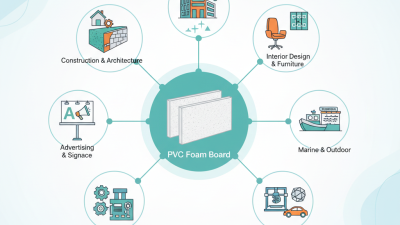

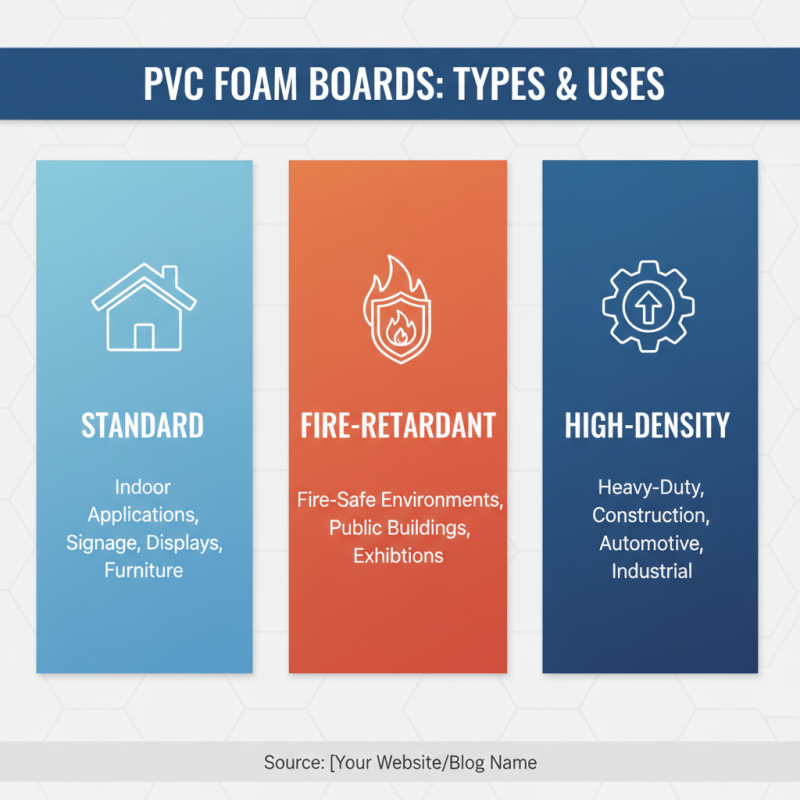

PVC foam boards are versatile materials widely used in various applications, from signage to construction. Understanding their types and characteristics is essential for selecting the right product for your project. Generally, PVC foam boards are categorized into three main types: standard, fire-retardant, and high-density foam boards. Standard boards are ideal for indoor applications, while fire-retardant variants are designed specifically for environments where fire safety is a concern. High-density foam boards offer enhanced durability and load-bearing capabilities, making them suitable for heavy-duty applications.

A crucial characteristic of PVC foam boards is their density, which affects both weight and strength. According to industry reports, the density of PVC foam boards typically ranges from 0.30 g/cm³ to 0.80 g/cm³, impacting their firmness and usability in different contexts. Moreover, these boards exhibit excellent moisture resistance, UV stability, and chemical resistance, making them suitable for outdoor usage and exposure to various environmental conditions. Furthermore, their aesthetic appeal and smooth surface allow for easy printing and finishing, ensuring they meet the visual requirements of modern design projects. Understanding these nuances will help you make informed decisions and choose a PVC foam board that perfectly aligns with the specific needs of your endeavor.

When selecting the right PVC foam board for your projects, it’s essential to consider a few key factors to ensure optimal results. One vital aspect is the board’s density, which typically ranges from 0.3 to 1.0 g/cm³. Higher density boards offer superior durability and resistance to impact, making them ideal for applications that require longevity, such as signage and display features. Reports from the PVC Foam Board Association estimate that using high-density boards can increase product lifespan by up to 50%, making them a wise investment for long-term projects.

Another important factor is the thickness of the PVC foam board. Common thicknesses range from 3mm to 19mm, with thicker boards providing more rigidity, which is crucial for structural applications. For instance, a report by Global Industry Analysts highlights that thicker boards are often preferred in the construction and architectural sectors due to their enhanced stability under load.

**Tip:** Always assess the specific requirements of your project before choosing the thickness and density of the board. For lightweight, decorative applications, lower thickness may suffice, while heavy-duty uses will warrant thicker options.

Finally, consider the finish of the board. Options include smooth, textured, or matte surfaces, each serving different aesthetic and practical purposes. A smooth finish can be ideal for printing and focuses on visual clarity, while a textured finish might assist in hiding scratches. According to industry insights, choosing the right surface can significantly affect the visual appeal, which is crucial in marketing and branding scenarios.

**Tip:** Sample different finishes before finalizing your choice to ensure they meet your project’s visual and functional criteria.

When selecting PVC foam boards for various projects, understanding their applications is crucial for achieving optimal results. One of the most popular uses for PVC foam boards is in signage and displays. Their lightweight nature and easy-to-print surface make them an ideal choice for creating both indoor and outdoor signage. They are weather-resistant and maintain their color vibrancy, ensuring that messages remain clear and attractive over time. As such, they are frequently employed in retail environments, exhibitions, and event promotions.

Another significant application of PVC foam boards is in construction and interior design. They are often utilized for wall cladding, decorative panels, and even furniture components due to their durability and versatility. PVC foam boards can be easily cut, shaped, and painted, allowing for creative designs that can enhance the aesthetics of a space. Additionally, they are resistant to moisture, making them perfect for kitchens and bathrooms where traditional materials might warp or degrade. By choosing the right thickness and finish, designers can create custom solutions tailored to their specific needs, ensuring both functionality and style in any project.

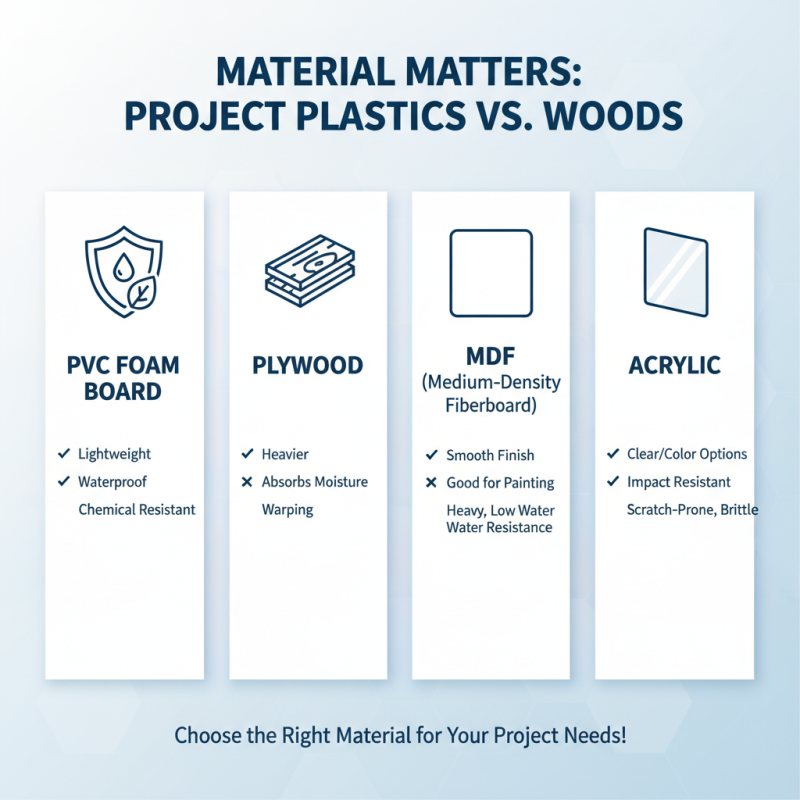

When choosing the right materials for your projects, understanding the differences between PVC foam board and other commonly used materials such as plywood, MDF, and acrylic is essential. PVC foam boards are lightweight, waterproof, and resistant to chemicals, making them suitable for a variety of applications, including signage and interior decor. Unlike traditional plywood, which can warp and absorb moisture, PVC foam boards maintain their shape and integrity over time. In contrast, MDF offers excellent surface finishing for painting but is heavier and less resistant to water, making it less ideal for outdoor uses.

When comparing PVC foam board to acrylic, the choice largely depends on the desired finish. Acrylic provides a glossy, clear appearance ideal for displays and high-end applications, while PVC foam boards offer a more matte finish that is equally effective for signage and low-cost applications. Moreover, acrylic can shatter upon impact, whereas PVC foam board is more forgiving and durable in various conditions.

**Tips:** When deciding between materials, consider the environmental conditions of your project location. If the product will be used outdoors or in moisture-prone areas, PVC foam board is a better choice due to its water-resistant properties. Additionally, if a lightweight and manageable option is necessary, PVC foam boards can simplify handling and installation. Always assess the specific requirements of your project to ensure optimal material selection.

When selecting PVC foam boards for various projects, sourcing high-quality materials is crucial to ensure durability and performance. According to industry reports, the global PVC foam board market is projected to grow significantly, driven by increasing applications in signage, interior finishing, and furniture manufacturing. As such, the importance of choosing the right PVC foam boards cannot be overstated.

**Tip 1:** Always check for certification and compliance with standards. Reliable suppliers should adhere to ISO or ASTM certification, which guarantees that the products meet specific industry quality requirements. This ensures that the boards not only meet aesthetic needs but also perform well in terms of strength and resistance to environmental factors.

**Tip 2:** Consider the thickness and density of the PVC foam boards. Research indicates that the density can affect the material's resistance to impact and bending. For projects requiring high durability, opting for higher-density boards will provide better performance. Additionally, evaluating the intended use can guide you in selecting the right thickness, as different applications may demand varying degrees of strength and flexibility.

By being mindful of these sourcing tips, you can enhance the quality of your projects while also ensuring that your choice of PVC foam boards aligns with industry standards and demands.

The chart below showcases the quality ratings of PVC foam boards based on their thickness, helping you choose the right material for your projects.