- Ginazhao@wanglumaterial.com

- Mon - Sat at 7:00AM to 9:00PM

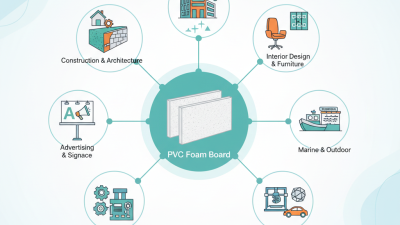

PVC Foam Board is a versatile material used across various industries. Its lightweight, waterproof, and durable properties make it a preferred choice for signage, construction, and display applications. According to industry reports, the global PVC foam board market was valued at approximately $1.2 billion in 2020, with an expected growth rate of over 5% annually.

The construction industry, in particular, heavily utilizes PVC Foam Boards. They are ideal for interior applications such as partitions and wall cladding. The ability of PVC Foam Boards to simulate different textures also adds to their appeal. Additionally, the sign-making industry depends on this material for producing high-quality and long-lasting signs. However, there are environmental concerns regarding the disposal of PVC products, which need addressing.

Despite their wide use, some professionals struggle with PVC Foam Board’s recyclability. While it offers many benefits, the industry must continue to find sustainable practices. As demand rises, it is crucial to balance efficiency with environmental responsibility. Therefore, recognizing challenges in the use of PVC Foam Boards is essential for fostering better solutions.

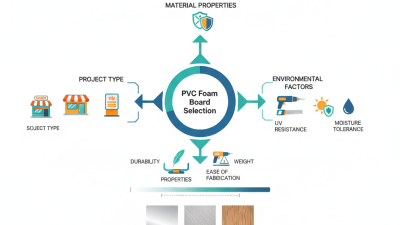

PVC foam board is a lightweight, versatile material known for its exceptional properties. This synthetic board is composed of polyvinyl chloride, which is foamed to create a rigid, durable structure. It possesses a closed-cell structure, making it resistant to moisture and chemicals. The non-toxic nature and easy handling characteristics elevate its usability across various industries.

One notable aspect of PVC foam board is its insulation properties. According to recent industry reports, it can provide up to 80% thermal insulation efficiency in construction applications. This makes it a preferred choice for building signage and interior displays. However, while it offers impressive qualities, some industry professionals note that it can be prone to warping under extreme heat. Furthermore, its long-term environmental impact raises questions about sustainability and recyclability.

In creative fields, the aesthetic potential of PVC foam board is significant. It can be easily cut, shaped, and printed on. Reports show that nearly 30% of signage manufacturers now incorporate this material. Yet, the reliance on such plastic-based solutions requires reflection on our dependency on non-biodegradable resources. Consequently, while PVC foam board showcases remarkable benefits, it's essential to consider its overall ecological footprint in industrial applications.

PVC foam board is a versatile material used in various industries. Its lightweight nature makes it ideal for signage, displays, and creative projects. The global PVC foam board market was valued at approximately $1 billion in 2022, with growth driven by its durability and ease of handling.

Key benefits of using PVC foam board include its resistance to moisture and chemical exposure. This makes it perfect for applications in the advertising and construction sectors. In fact, the construction and building materials segment accounted for over 30% of the market share last year. Users appreciate that PVC foam boards can be easily cut, drilled, and glued, allowing for customization in design.

Tips for working with PVC foam board: Always use sharp tools for cutting to achieve clean edges. Consider using a heat gun for bending the material smoothly. However, keep in mind that excessive heat can warp it. While it holds paint well, surface preparation is essential for an even finish. Remember to test on a small piece first to ensure a satisfactory result.

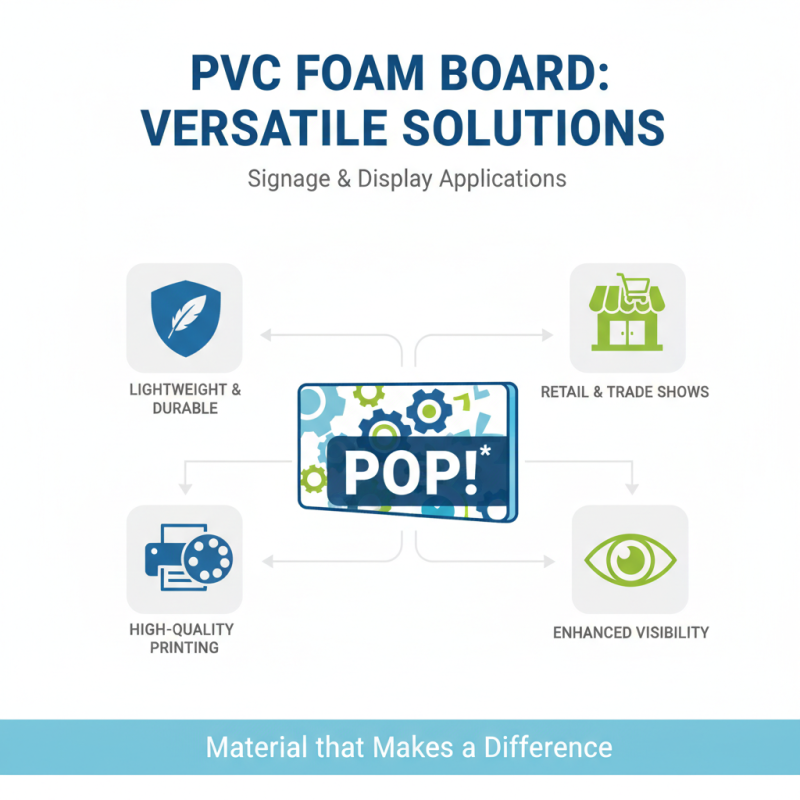

PVC foam board is a versatile material widely used in signage and display solutions. Its lightweight nature and durability make it ideal for various applications. From trade shows to retail displays, this material can enhance visibility and attract attention. The smooth surface allows for high-quality printing, making graphics pop.

A popular use is in indoor signage. Businesses use PVC boards for directional signs or promotional displays. They can withstand indoor conditions without warping or fading. For outdoor applications, while PVC foam boards can be effective, they may require additional protection against harsh weather.

Exhibitors often choose PVC foam boards for their booths. They create eye-catching backdrops or product displays. However, improper handling can lead to scratches or dents. This aspect requires careful planning and consideration when designing displays. The balance between affordability and durability is crucial in maximizing the benefits of using PVC foam boards.

PVC foam board plays a significant role in construction and architectural projects. This material is lightweight yet sturdy, making it an excellent choice for various applications. The ease of handling allows architects and builders to create intricate designs without excessive labor. However, designers must consider its limitations. While it is cost-effective, it may not support heavy loads like some traditional materials.

In design, the versatility of PVC foam board is evident. It can be easily cut, shaped, and printed upon. This adaptability makes it suitable for signs, displays, and interior partitions. Its water resistance enhances its performance in humid environments. Yet, it sometimes lacks the aesthetic depth of more premium materials. Balancing cost and appearance is a common challenge for many project planners.

Sustainability also raises questions around PVC foam boards. While they offer functional benefits, their environmental impact cannot be overlooked. Recycling options exist, though they are often not widely accessible. This contrast invites ongoing reflection on best practices within the industry. Embracing alternative materials may lead to better outcomes for both projects and the planet.

PVC foam board is gaining popularity in various industries due to its unique characteristics. Unlike traditional materials like plywood or metal, PVC foam board is lightweight and flexible. This makes it easy to handle and install. Its water resistance also sets it apart, making it ideal for humid environments. Many professionals have noticed that it requires less maintenance than wood or metal.

However, some users point out that PVC foam board may not be as strong as solid wood. In high-stress applications, wood can offer better durability. Additionally, the aesthetic appeal of wood is hard to replicate with synthetic materials. While PVC foam board is versatile, it sometimes lacks the timeless charm of traditional materials.

Moreover, while installation is easier, working with PVC foam board can pose challenges. Cutting it requires specific tools to avoid rough edges. In contrast, wood can be shaped with common tools. So, when selecting materials, it's essential to weigh the pros and cons. The right choice often depends on the project's specific needs and challenges.

| Material | Weight (kg/m²) | Cost ($/m²) | Durability (Years) | Common Applications |

|---|---|---|---|---|

| PVC Foam Board | 2.5 | 10 | 5-10 | Signage, Display, Construction |

| Acrylic | 3.5 | 30 | 7-15 | Display Cases, Windows, Signs |

| Plywood | 8.5 | 15 | 10-20 | Furniture, Construction, Shelving |

| Aluminum Composite Panel | 5.0 | 25 | 15-30 | Facades, Signage, Interior Design |