- Ginazhao@wanglumaterial.com

- Mon - Sat at 7:00AM to 9:00PM

PVC foam board has emerged as a versatile material widely adopted across various industries due to its exceptional properties and numerous benefits. This lightweight yet durable material, made from polyvinyl chloride, offers an excellent balance of affordability and performance, making it a preferred choice for applications ranging from signage to construction. With its smooth surface and ease of fabrication, PVC foam board allows for intricate designs and high-quality finishes, catering to both functional and aesthetic needs in diverse sectors.

The applications of PVC foam board are extensive, including interior design, advertising, and even marine environments. Its resistance to moisture, chemicals, and impacts makes it ideal for locations subjected to harsh conditions, ensuring longevity and reliability. Furthermore, the material is easy to cut, shape, and paint, which enhances its adaptability for custom projects. As industries continue to explore innovative solutions, PVC foam board stands out for its capability to meet challenging requirements while providing a sustainable alternative to other materials.

As we delve into the top uses and benefits of PVC foam board in various industries, it becomes evident that this remarkable material not only fosters creativity but also contributes to more efficient and effective outcomes, solidifying its position as an essential component in modern manufacturing and design.

PVC foam board, composed primarily of polyvinyl chloride, is a lightweight and versatile material that has gained popularity across various industries. It consists of a closed-cell structure, which gives it durability and a smooth surface finish. The material is resistant to moisture, chemicals, and UV rays, making it ideal for both indoor and outdoor applications. Additionally, PVC foam boards can be easily shaped, cut, or fabricated, allowing for a wide range of uses from signage to furniture production.

When working with PVC foam board, it’s essential to consider a few tips to maximize its benefits. First, always use appropriate tools for cutting, such as a fine-toothed saw or a utility knife, to ensure clean edges and avoid damaging the material. Second, for printing or painting, ensure that the surface is properly cleaned and primed to enhance adhesion and achieve the best finish. Lastly, when installing in outdoor environments, consider using UV-resistant coatings or treatments to prolong the life of the board and maintain its appearance.

These characteristics make PVC foam board an excellent choice for numerous applications, such as displays, exhibition booths, and even architectural features. Its versatility and ease of processing make it a favored option in industries like advertising, construction, and interior design, where both functionality and aesthetics are paramount.

| Industry | Uses | Benefits |

|---|---|---|

| Signage | Display boards, outdoor signs | Weather resistant, lightweight |

| Construction | Partitions, wall cladding | Durable, easy to install |

| Advertising | Point of sale displays, promotional material | Vibrant print quality, customizable |

| Automotive | Interior panels, dashboards | Lightweight, impact resistant |

| Aerospace | Filler materials, lightweight structures | High strength-to-weight ratio |

| Furniture | Cabinets, tables | Easy to clean, modern finish |

| Arts and Crafts | Model making, creative projects | Versatile, easy to cut and shape |

PVC foam board has gained significant traction across various industries due to its unique properties that enhance versatility. One of the key characteristics of PVC foam board is its lightweight nature. This makes it easy to handle and install, reducing labor costs and making transportation simpler. Additionally, the material is corrosion-resistant and waterproof, contributing to its longevity and making it suitable for both indoor and outdoor applications. These qualities enable it to endure harsh environments while maintaining aesthetic appeal.

Another notable property is the board's excellent insulation capabilities. PVC foam board offers effective thermal and sound insulation, making it an ideal choice for the construction and signage industries. Its smooth surface allows for easy printing and painting, enabling vibrant graphics and designs that are essential for marketing purposes. Furthermore, the flexibility of PVC foam board allows it to be easily cut and shaped, allowing for custom applications tailored to specific needs. These attributes collectively enhance its usability, making it a preferred choice across sectors ranging from advertising to furniture design.

PVC foam board has gained widespread acceptance across various industries due to its versatility, durability, and lightweight properties. In the construction sector, it is frequently used for interior applications such as partition walls and ceilings. According to a report by MarketsandMarkets, the global demand for PVC foam boards in construction is expected to grow at a CAGR of 5.4% from 2021 to 2026, driven by increased urbanization and the need for sustainable building materials. Its resistance to moisture and termites further enhances its suitability for both residential and commercial projects.

In the advertising and signage industry, PVC foam board is a favored material for creating eye-catching displays. The material is printable, easy to cut, and can be easily fabricated into different shapes, making it ideal for indoor and outdoor signs. As highlighted by Allied Market Research, the global signage market is projected to reach $34.8 billion by 2026, with a significant portion of this attributed to PVC foam signs. Furthermore, the graphic design industry benefits from the material's smooth surface which allows for high-quality graphics and branding, ultimately contributing to increased consumer engagement.

The automotive industry also leverages PVC foam boards for various applications including interior panels and insulation. The lightweight nature of PVC foam contributes to improved fuel efficiency, addressing a growing demand for eco-friendly solutions in automotive manufacturing. Research by the International Council on Clean Transportation indicates that reducing vehicle weight by just 10% can improve fuel efficiency by about 6-8%. This trend highlights the importance of materials like PVC foam board in supporting technological advancements aimed at sustainable transportation solutions.

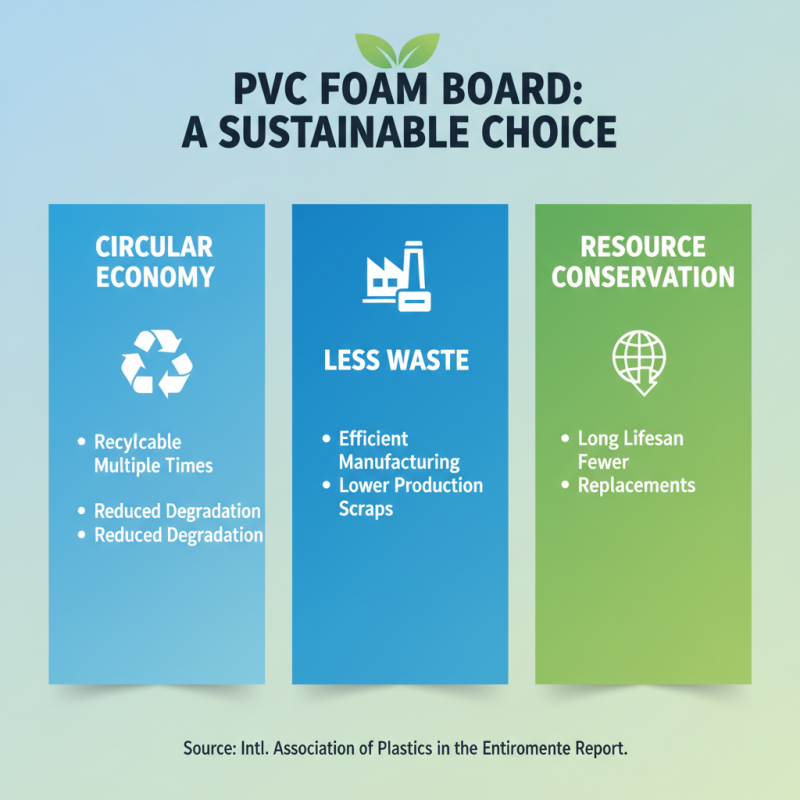

PVC foam board, a lightweight and versatile material, has garnered attention for its environmental benefits and sustainability within various industries. A recent report from the International Association of Plastics in the Environment highlights that PVC products can be recycled multiple times without significant degradation, which supports a circular economy. When compared to traditional materials like wood and metal, PVC foam board produces less waste during manufacturing, and its long lifespan means fewer replacements are needed, reducing overall resource consumption.

Additionally, the low energy consumption associated with the production of PVC foam board contributes to its sustainability. According to the European Commission's report on plastics, manufacturing PVC foam boards uses 30% less energy compared to other substrates like MDF or plywood. Furthermore, advances in technology have led to innovations in the recycling processes of PVC materials, ensuring that post-consumer waste is effectively repurposed. This aligns with the growing trend towards sustainable building practices and materials, making PVC foam board a preferred choice for many eco-conscious industries.

The future of PVC foam board technology is showing promising trends that are reshaping its application across various industries. Advances in production techniques, such as the integration of automated manufacturing processes, have led to greater efficiency and reduced waste in the creation of PVC foam boards. According to a recent industry report from MarketsandMarkets, the global PVC market is expected to reach USD 77.2 billion by 2026, reflecting a compound annual growth rate (CAGR) of 4.0% from 2021. This growth is driven by an increased demand for lightweight, durable, and versatile materials in construction, signage, and interior design sectors.

Moreover, innovations in PVC foam board composition, including the incorporation of eco-friendly additives, are enhancing performance while reducing environmental impact. The green building movement is significantly influencing the material choices in construction, with PVC foam boards being favored for their recyclability and energy-efficient properties. Additionally, advancements in surface finishes and textures are expanding the aesthetic appeal of PVC foam boards, making them more attractive for design applications.

A study by Technavio predicts that the demand for PVC foam boards in the interior design market will grow by over 10% annually until 2025, signaling a robust future for this versatile material as industries continue to seek sustainable and functional solutions.